The concentration range of the tube printer is between 1-7, and the factory setting

of the machine is generally 3 or 4.

线号机浓度什么时候调整

When will the density of the tube printer be adjusted?

线号机的浓度范围在1-7之间,机器出厂设置一般为3或4,有时候天气特别冷,会出现打印不清楚的情况,这时候就需要将打印浓度相对调高了。

The concentration range of the tube printer is between 1-7, and the factory setting of the machine is generally 3 or 4. Sometimes, the weather is particularly cold, and there may be unclear printing. At this time, it is necessary to increase the printing concentration relatively.

线号机浓度是更常用的调节内容,也是容易忽视的调节项,售后有遇到客户反映打印套管热缩管的时候印字不清楚,结果是打印浓度调整的太浅了,也有遇到客户同时使用两台一样的线号机,也使用同样的耗材,色带和热缩管,但是打印出来的效果却不一样,更后发现,也是打印浓度调整的数值不一样造成的。一般来说,多数线号机的打印浓度范围在1-7之间,机器出厂的设置或者默认设置多为3或者4,新机器的这种设置一般能够符合绝大多数的耗材的使用要求,不过也有少数情况,套管或者热缩管的要求比较特殊,需要略微调高打印浓度,才能够打印出好的效果。

Tube printer density is the most commonly used adjustment content, and it is also an adjustment item that is easily overlooked. After-sales service, some customers reported that the printing was not clear when printing casing heat shrink tubes, and the result was that the printing density was adjusted too shallow. Some customers also encountered Two machines with the same thread size were used at the same time, and the same consumables, ribbons and heat shrink tubes were used, but the printing effects were different. Later, it was found that it was also caused by the different values of the printing density adjustment. Generally speaking, the printing density range of most line number machines is between 1 and 7. The factory setting or default setting of the machine is mostly 3 or 4. This setting of new machines can generally meet the usage requirements of most consumables. However, there are also a few cases where the requirements for sleeves or heat shrink tubes are relatively special, and the printing density needs to be slightly increased to achieve good printing results.

而线号机浓度调到更高,有时候也会粘到套管上,和套管一起出来的情况,下面就是硕方针对线号机浓度提出的建议:

When the concentration of the tube printer is adjusted to a higher level, sometimes it may stick to the casing and come out together with the casing. The following are the suggestions put forward by ZOTA regarding the concentration of the tube printer:

夏季气温高,线号机的操作环境温度往往过高,色带容易被烫断。建议您:

The temperature is high in summer, and the operating environment temperature of the tube printer is often too high, and the ribbon is easily burned. suggest you:

1、将线号机浓度调至2或1,字迹可打印清晰即可。

1.Adjust the density of the tube printer to 2 or 1, as long as the writing can be printed clearly.

2、选用夏天用的PVC套管(管壁相对较厚)。

2.Choose PVC casing for summer use (the pipe wall is relatively thick).

反之,冬天的时候,大部分地区的线号机的操作环境温度会过低,这种情况下,会出现打印效果不清晰,PVC套管走管速度低于正常水平的状况。

On the contrary, in winter, the operating environment temperature of tube printer in most areas will be too low. In this case, the printing effect will be unclear and the PVC casing running speed will be lower than the normal level.

建议您:

suggest you:

1、将线号机浓度调至4或5或6(不同地区气候不温同需要的浓度各不相同),直到字迹可打印清晰;

1.Adjust the thread density of the machine to 4, 5, or 6 (different regions have different climates and require different concentrations) until the writing can be printed clearly;

2、选用冬天用的PVC套管(管壁相对较薄)。

2.Choose PVC casing for winter use (the pipe wall is relatively thin).

浓度设置方法:

concentration setting method:

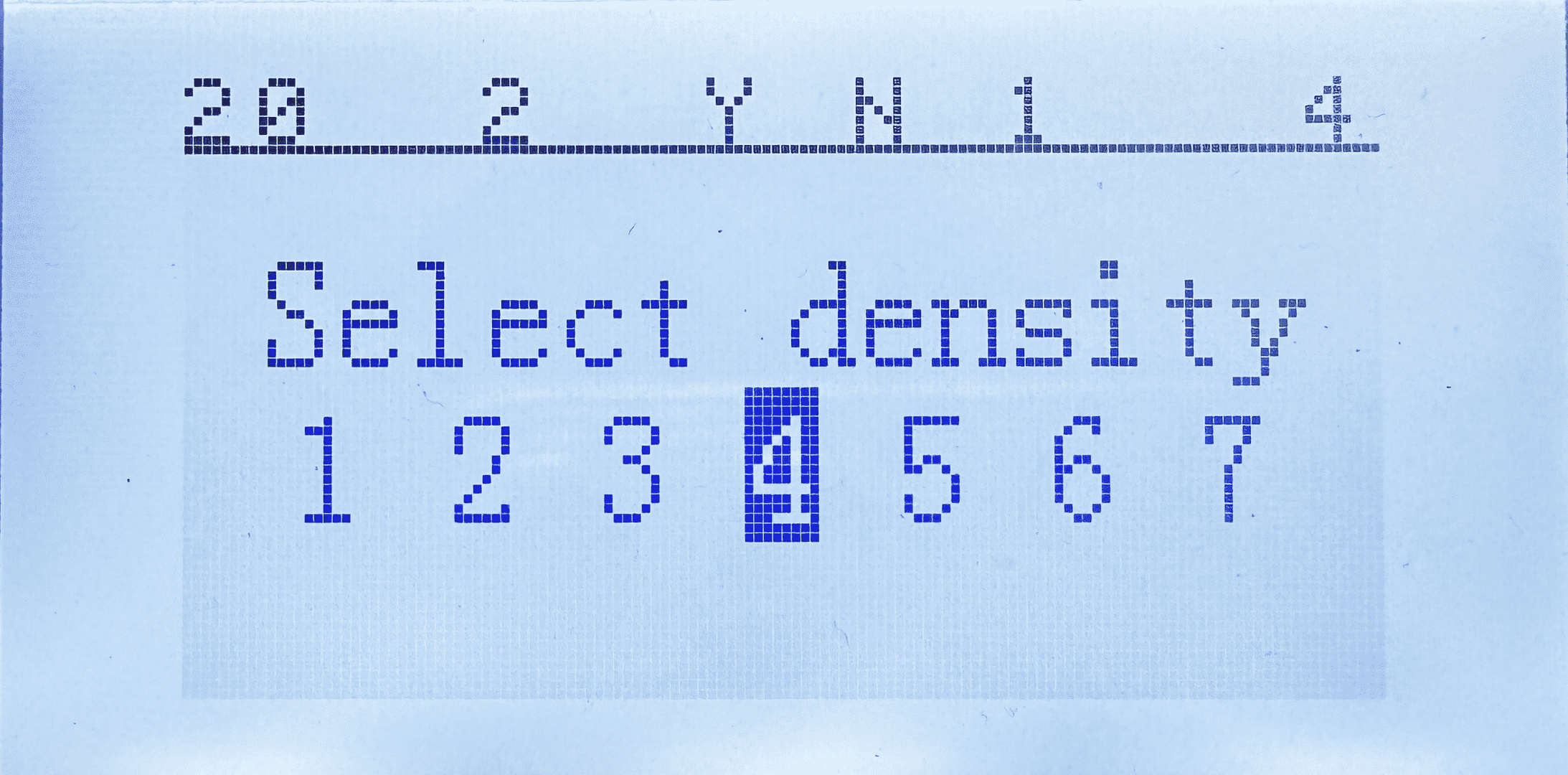

按“浓度”按键,会出现如下界面:

Press the “Concentration” button, the following interface will appear:

按【→】或【←】,选定后,按【Enter】,则完成设定,并自动返回文档输入界面。1,2,3,4,5,6,7打印浓度依次加深。

Press [→] or [←], select and press [Enter] to complete the setting and automatically return to the document input interface. The printing density of 1, 2, 3, 4, 5, 6, and 7 becomes darker in sequence.

请依据环境温度选择打印浓度:夏天时温度高,请选择从1开始的较低打印浓度。

Please select the printing density according to the ambient temperature: in summer, when the temperature is high, please choose a lower printing density starting from 1.

以上就是卓泰线号机生产厂家关于线号机浓度调整的详细介绍,希望广大用户使用线号机时能多注意,如果对上述介绍存在疑问,或者想了解更多关于硕方线号机的信息,可以来电咨询卓泰线号机厂家:000-00000000,或者拨打卓泰全球售后服务热线:400-000–0000。

The above is the detailed introduction of the ZOTA tube printer manufacturer on the concentration adjustment of the wire gauge machine. I hope that users can pay more attention when using the wire gauge machine. If you have questions about the above introduction, or want to know more about ZOTA tube printer For information, you can call ZOTA tube printer manufacturer: 000-00000000, or call ZOTA global after-sales service hotline: 400-000-0000.